- English

- Indonesia

Published by I Putu Arka Suryawan at Sat May 24 2025

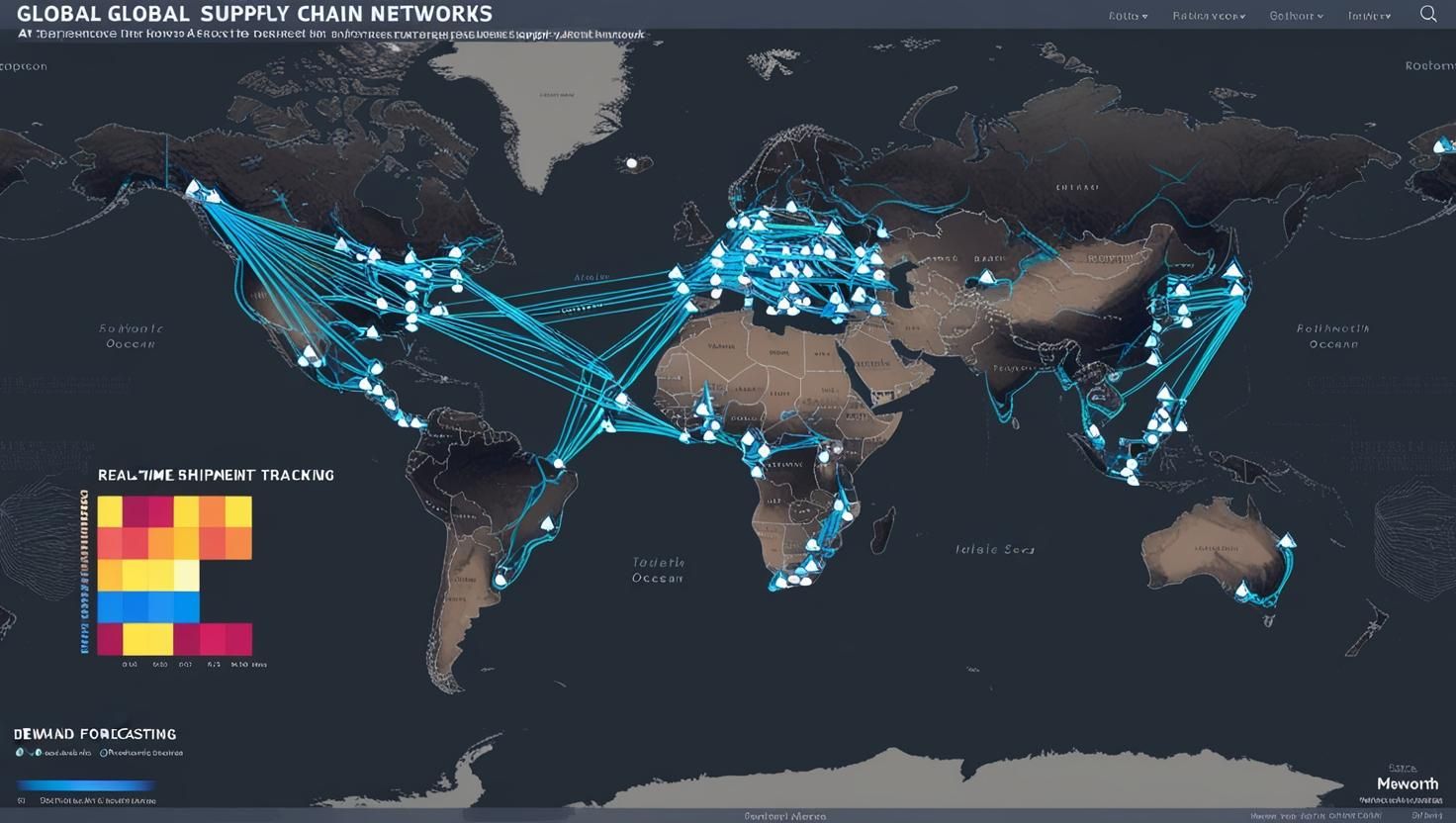

The modern supply chain is a complex web of interconnected processes, suppliers, and customers spanning across continents. Traditional management approaches often struggle to keep pace with today's dynamic market demands, unpredictable disruptions, and ever-increasing customer expectations. This is where artificial intelligence steps in as a game-changer, offering unprecedented visibility, prediction capabilities, and automation that revolutionize how businesses manage their supply chains.

Artificial intelligence in supply chain management isn't just about automating repetitive tasks—it's about creating intelligent systems that can learn, adapt, and make decisions in real-time. These AI-powered solutions analyze vast amounts of data from multiple sources, identify patterns that humans might miss, and provide actionable insights that drive better business outcomes.

The beauty of AI lies in its ability to process information at scale while maintaining accuracy. Where traditional systems might take hours or days to analyze market trends and inventory levels, AI can do this in minutes, allowing businesses to respond quickly to changing conditions and maintain optimal efficiency throughout their operations.

One of the most impactful applications I've witnessed involves a major retail chain that implemented AI-powered demand forecasting. Their traditional approach relied on historical sales data and seasonal patterns, often resulting in either excess inventory or stockouts. By integrating machine learning algorithms that considered weather patterns, local events, social media sentiment, and economic indicators, they achieved a 35% improvement in forecast accuracy.

The system continuously learns from new data, adjusting predictions based on emerging trends and unexpected events. During the pandemic, while many retailers struggled with demand volatility, this AI system quickly adapted to changing consumer behaviors, helping the company maintain optimal inventory levels and reduce waste by 28%.

A manufacturing client transformed their maintenance strategy using AI-powered predictive analytics. Instead of following rigid maintenance schedules or waiting for equipment failures, they now use sensors and machine learning to predict when machines need attention. This proactive approach reduced unplanned downtime by 45% and extended equipment lifespan by an average of 18 months.

The AI system monitors vibration patterns, temperature fluctuations, and performance metrics in real-time, identifying subtle changes that indicate potential issues. Maintenance teams receive alerts with specific recommendations, allowing them to address problems before they impact production schedules.

Transportation costs represent a significant portion of supply chain expenses, making route optimization crucial for profitability. I've helped implement AI solutions that consider real-time traffic conditions, weather forecasts, delivery time windows, and vehicle capacity constraints to determine optimal routes.

One logistics company saw remarkable results: 22% reduction in fuel costs, 30% improvement in on-time deliveries, and 15% increase in daily delivery capacity. The AI system continuously learns from driver feedback and real-world conditions, becoming more accurate over time.

The success of any AI supply chain initiative heavily depends on data quality and integration capabilities. Many organizations struggle with siloed systems, inconsistent data formats, and incomplete information. I've learned that addressing these challenges requires a systematic approach that prioritizes data governance and standardization.

Successful implementations often start with a comprehensive data audit, identifying sources, quality issues, and integration requirements. Organizations need to invest in data cleansing processes and establish clear protocols for data collection and maintenance. This foundation work, while time-consuming, is essential for AI systems to deliver accurate insights.

AI implementation isn't just a technical challenge—it's an organizational one. Supply chain optimization touches multiple departments, from procurement and manufacturing to sales and customer service. I've found that successful projects require strong collaboration between IT teams, supply chain professionals, and business stakeholders.

Regular communication, shared objectives, and clear accountability help ensure that AI solutions align with business needs and deliver practical value. Training programs and change management initiatives are equally important to help teams adapt to new AI-powered processes.

Measuring the impact of AI on supply chain efficiency requires carefully selected metrics that reflect both operational improvements and business value. I typically focus on several key areas: inventory turnover rates, order fulfillment accuracy, delivery performance, cost reduction, and customer satisfaction scores.

The most successful implementations show improvements across multiple dimensions. For instance, better demand forecasting leads to optimized inventory levels, which reduces carrying costs while improving service levels. Enhanced route optimization reduces transportation expenses while improving delivery reliability, directly impacting customer satisfaction.

Beyond immediate operational improvements, AI supply chain optimization creates lasting competitive advantages. Companies develop better supplier relationships through improved collaboration and transparency. They become more resilient to disruptions by having better visibility and faster response capabilities.

I've observed that organizations with mature AI supply chain systems often discover new revenue opportunities. Better demand understanding enables them to introduce products more strategically, while improved operational efficiency allows them to offer competitive pricing or invest in innovation.

The supply chain AI landscape continues evolving with emerging technologies like edge computing, 5G connectivity, and advanced IoT sensors. These developments enable more sophisticated real-time decision-making and expand AI capabilities to previously challenging areas.

Blockchain integration with AI systems promises enhanced transparency and traceability, while augmented reality applications help warehouse workers make better decisions based on AI recommendations. The convergence of these technologies creates exciting possibilities for even more intelligent and efficient supply chains.

Modern supply chain optimization increasingly considers environmental impact and ethical considerations. AI systems can optimize routes to reduce carbon emissions, minimize packaging waste, and ensure sustainable sourcing practices. Organizations are also focusing on responsible AI development, ensuring their systems make fair and transparent decisions.

The future belongs to companies that can balance efficiency, sustainability, and ethical considerations in their AI implementations. This holistic approach not only improves operational performance but also aligns with growing stakeholder expectations for responsible business practices.

Supply chain optimization through AI represents more than just a technological upgrade—it's a fundamental shift toward more intelligent, responsive, and sustainable business operations. The examples and insights shared here demonstrate that successful implementation requires careful planning, quality data, and strong organizational commitment, but the results speak for themselves in terms of improved efficiency, reduced costs, and enhanced customer satisfaction.